Key messages:

- in 2023 to 2024 we have seen improvements in the industry’s investigation of Signals Passed at Danger (SPADs) where the RSSB incident factors have been used. However, the number of SPADs that are attributable to driver’s actions increased in 2023 to 2024, we consider that industry is at the limit of human reliability and there will not be a significant change until there is a committed, settled, industry-wide approach to future train protection and speed supervision. We welcome Network Rail’s Control Period 7 business plan commitment to explore a driver speed advisory system that would give the driver real-time speed limit and exceedance information as well as automatic over-speed braking

- train operating companies are not implementing effective change management when modifying existing train fleets and introducing new fleets. This is too often leading to a regression in risk mitigation, replacing reasonably practicable engineering controls with human intervention

The mainline operators comprise charter operators, passenger train operators (TOC) and freight operating companies (FOC) that operate over infrastructure controlled by Network Rail and Amey Infrastructure Wales Limited (Seilwaith Amey Cymru).

Signals Passed at Danger (SPAD)

2023 to 2024 was the final year of our 3-year inspection of SPAD management by passenger and freight operators. We targeted the operators' own investigations of their most serious SPADs occurring in the work-year. We found that increased use by driver managers of the RSSB incident factors (described in our report last year) had improved the quality of their investigations. Along with knowledge and application of non-technical skills, this led to improved development plans for drivers designed to reduce the likelihood of recurrence.

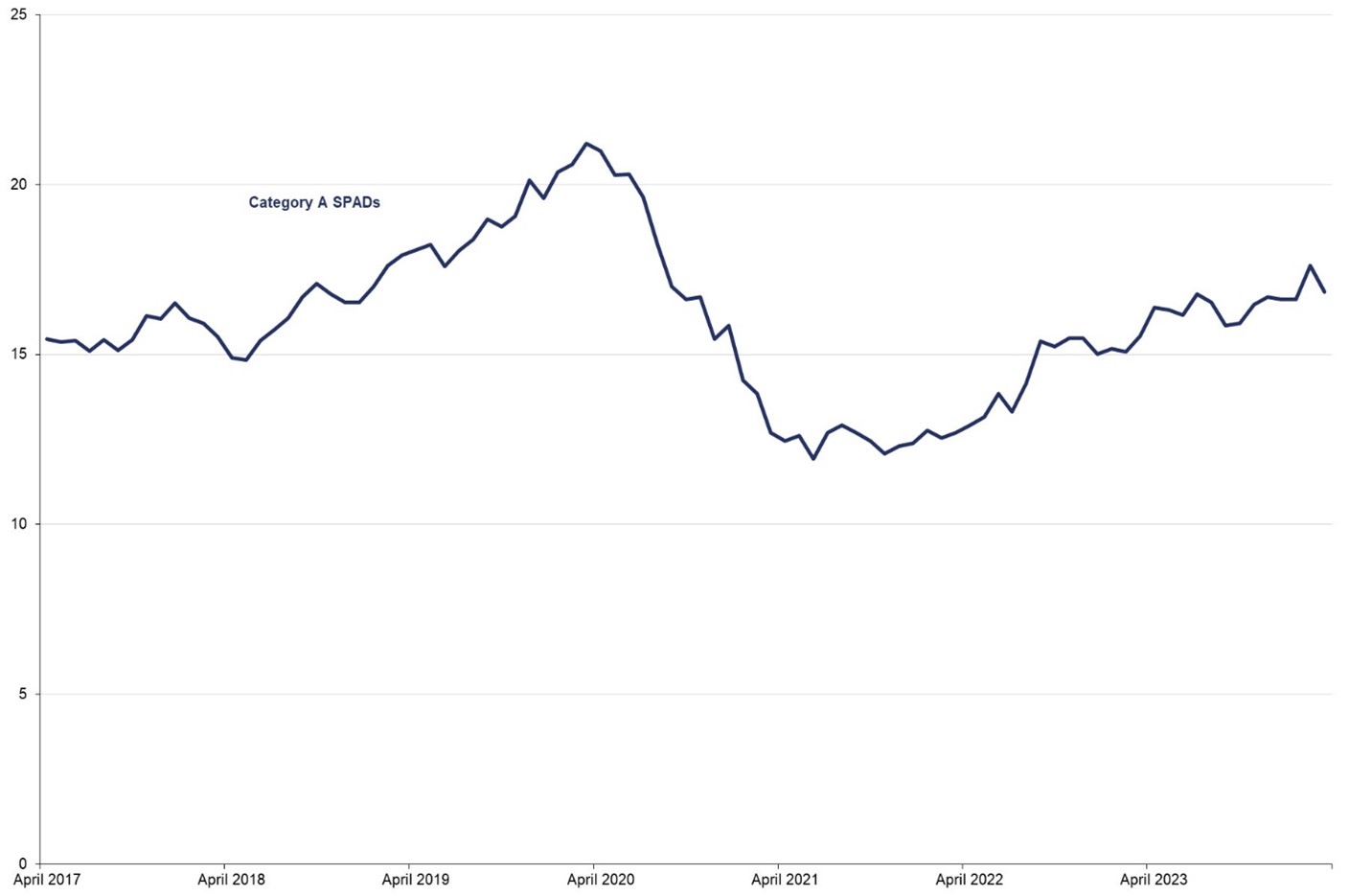

There has been an increase in the most serious (category A) SPADs which are attributable to drivers actions over the last 3 years. In March 2023 the annual moving total was 10 Category A SPADs and in March 2024 it was 13 SPADs. We continue to investigate all Category A SPADs because of the potential for a catastrophic outcome along with incidents where drivers have significantly exceeded the line speed (over speeding).

Figure 4: SPADs

Source: Rail Delivery Group

This year we have undertaken permissioning work associated with the introduction of the European Train Control System (ETCS) on lines from Old Oak Common to Heathrow Airport. ETCS operation is a higher level of risk control than the Train Protection and Warning System (TPWS) which it supersedes. ETCS is a speed supervision system and provides mitigation against overspeeding and SPADs.

Further schemes are coming online. The 18km section of the East Coast mainline between Welwyn and Hitchin migration to ETCS is planned for 2025. We are working with passenger and freight operators, through our attendance at industry risk groups, to ensure there is cooperation with Network Rail and they are ready for the transition, so that the benefits of ETCS are realised early and the migration is not drawn out. In terms of reducing the number of SPADs, we consider that industry is at the limit of human reliability and there will not be a significant reduction in SPADs until there is a committed, settled, industry-wide approach to future train protection and speed supervision. We welcome Network Rail’s Control Period 7 business plan commitment to explore a driver speed advisory system that would give the driver real-time speed limit and exceedance information as well as automatic over-speed braking.

Rolling stock management

Operators of Mark 1 Rolling stock require exemption from regulation 4 of the Railway Safety Regulations 1999 (RSR), by demonstrating adequate crashworthiness and over-riding measures. This year we continued our work to assess the capability of these operators and undertook targeted inspections of vehicles and record keeping. Across all these inspections we found suitable arrangements were in place, with some operators going further; for example, by fitting removable inspection plates to allow more frequent inspection of vulnerable parts of the steel body prone to corrosion.

We have continued our focus on the use of hinged door rolling stock (relying on exemptions from regulation 5 of RSR). Many operators are now fitting Central Door Locking (CDL) to hinged door stock, and we have seen good progress in achieving their committed timescales. Also, in line with our policy, another operator improved risk controls by reducing their operating speed to 25mph. All of these operators have gone on to now address the associated risk from drop light windows, preventing a passenger or member of staff from leaning out of an open window and placing themselves in danger of serious personal injury.

Photo: Vintage trains fitment of a central locked door bolt

We have assessed the change management arrangements of operators introducing new trains. Our expectation is that operators will ensure health and safety by design and take the opportunity to improve risk control with technology, such as the extending steps on Stadler trains, which in most situations eliminates the gap at doorways between train and platform. Instead, we have seen operators remove reasonably practicable engineering controls, choosing instead risk controls reliant on people, for example the switching-off of speed supervision systems on existing fleets or introduction of replacement fleets without compatible equipment. This will be the subject of further investigation.

We also took action during the year to tackle non-compliance with the law in relation to rolling stock matters, with 2 Improvement Notices served on Chiltern Railways associated with arrangements in place for persons with reduced mobility.

Cyber security and software change management

We have continued to build upon the work undertaken in 2022 to 2023 to look at the control of safety risks posed by cyber security and poor software development and assurance arrangements. We conducted a number of inspections that looked at the processes train operators have in place to manage their digital systems, including software change management arrangements to ensure safe operation. This inspection work was aimed at developing an initial understanding of the rail sector’s management maturity in this rapidly changing area. Findings have been mixed with elements of good practice; however, the inspections have identified areas for improvement including improved cooperation between train operator safety and security teams to identify and mitigate safety risks and more robust supply chain and change management assurance. Further inspections are planned in the next work year.

Collaboration with industry groups

This year we have continued our support to industry groups including RSSB’s People on Trains and Stations Group (PTSRG), National Freight Safety Group (NFSG), Asset Integrity Group (AIG) and the Rail Wellbeing Alliance (RWA) as well as Rail Partners Passenger Operators Safety Forum. We have ‘observer’ status at these meetings, which gives us the opportunity to share and explain changes to our guidance, highlight emerging risks and efficiently raise other regulatory matters where the whole sector is affected. This year we became regular observers at the Freight Safe Steering Group, described in the case study below.

Case study 1: Freight Safe Steering Group collaboration in practice

Background

The NFSG reports into the Freight Safe Steering Group (FSSG), which in turn provides governance and assurance to the Rail Partners Freight Council for delivery of the industry’s Freight Safe Programme. The group was formerly known as the National Freight Safety Group Steering Group.

Observer status

ORR attends FSSG as an observer rather than full member and does not take part in decisions made by the group. For the next five years (Control Period 7 from 2024 to 2029), FSSG has a fund of £15.9 million to deliver strategic projects to improve health and safety in the sector. Our attendance now means we have a clear picture of the projects and their delivery. These projects include:

- Wagon Condition Programme – including;

- Engineering of wagons i.e. how they are built and maintained

- Train preparation and planning

- Technology lineside and on wagons to detect problems before failure

- Adhesion

- Contractual arrangements for safety critical equipment for European Entities in Charge of Maintenance operating in the UK

- Horizon scanning

- Freight Safe Insights - the development of a freight sector Precursor Indicator Model (PIM)

- climate change

The Wagon Condition Programme draws together several workstreams at risk of duplicating work to address RAIB recommendations for Llangennech and other incidents. As observers, ORR will have good oversight of the programme, and opportunity to influence, as we report on progress to address the RAIB recommendations.

The Horizon Scanning and Freight Safe Insights work will give us the opportunity to share with the sector our own thinking on emerging issues, such as ETCS preparedness and how fatigue is managed by the sector. We will also be able to draw from FSSG intelligence to inform our own health and safety risk profiling.

Platform Train Interface

Last year we highlighted the work being done by RSSB to revise its Platform Train Interface (PTI) Risk Assessment Tool (RAT). With challenge and support by ORR, RSSB and train operators have collaborated to refresh the tool, fix known issues, update existing features and add new functionality. Following a relaunch in 2023, the tool has attracted greater usage in the sector and improved collaboration on risk control available for different operators using the same platforms.

Excellent work was undertaken by RSSB in 2015 to develop a strategy for managing risks at the PTI. Through our membership of RSSB’s People on Trains and Stations Risk Group (PTSRG) we asked the group to review the 2015 strategy, as work around a wider ‘Rail Health and Safety Strategy’ was underway by RSSB this year. PTSRG committed to review the 2015 PTI strategy and this work is well underway with ORR represented in the working group.

Excellent work was undertaken by RSSB in 2015 to develop a strategy for managing risks at the PTI. Through our membership of RSSB’s People on Trains and Stations Risk Group (PTSRG) we asked the group to review the 2015 strategy, as work around a wider ‘Rail Health and Safety Strategy’ was underway by RSSB this year. PTSRG committed to review the 2015 PTI strategy and this work is well underway with ORR represented in the working group.

The 6 elements of the original strategy included:

- data and intelligence gathering

- passenger movement through the station and across the PTI

- train stopping positions, dispatch, monitoring the dispatch corridor and emergency stopping once dispatched

- optimising the step and gap

- accessibility, including how accessibility can be improved without affecting performance and safety, and

- performance and capacity

Early emerging thinking indicates that accessibility should not sit in isolation but be an integral part of the remaining 5 themes to be carried forward. ORR fully supports this approach and the groups’ focus on innovation and continuous improvement in risk control.